Don’t get fooled by the simplicity of measuring a box! Yes, it may be uncomplicated, but it is not easy to carry out this task. The reason behind being; your product’s safety is dependent on these measurements for sure. Critically studying the dimensions of your custom packaging boxes come in handy when you are calculating the expenses such as; production cost, shipping and storage cost along with the raw materials required for the manufacturing.

We have to remember that if there is less room for the product to move around in the box, it means that your product will be safe from damage. Moreover, this also reduces the production cost by far. Don’t be scared by the complexity of measuring a customized packaging box, because we have laid out a perfect guide to measuring boxes which will indeed help you a lot!

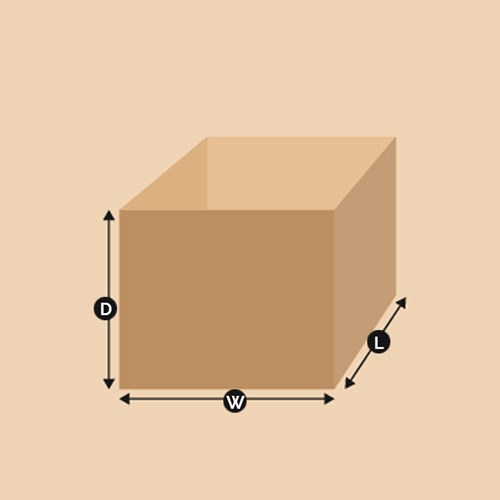

Let us first study the three dimensions of custom packaging boxes!

There are a few steps of taking box dimensions including;

- Understand and learn the most accurate way of measuring dimensions.

- Packaging boxes can measure by their length, width, and depth.

- Length or Height: this refers to the longest side of the box when you look from the left to right

- The width refers to the shorter side of the box when you look from the back to the front.

- Depth: this refers to the shortest side from top to bottom that is perpendicular to the length/height and breath

- If you are working with a conical shape for this, you need to measure two diameters from top and bottom and the Height of your cone. Also, print its template on a 100% scale to prevent any flaws and mistakes. Please acknowledge us if you use MAC System for scaling and printing templates because it will lead to uncertainty in dimension. So to avoid this, we recommend you print it on Windows operating system or print it in PDF format.

- Similarly, for round shape boxes, the measurement can be done by measuring its diameter or circumference to get the exact size of the box.

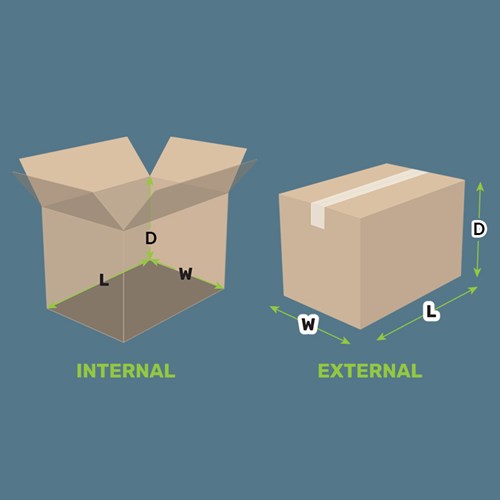

How important are the internal dimensions for packaging box measurements?

The packaging industry usually takes internal measurements as the preferred way of measuring boxes. The reason behind this is the accuracy they provide for production.

Manufacturers who know what they are doing are usually very picky about the packaging boxes’ exact dimensions (External and Internal). Measuring boxes right is crucial to ensure that your product is shipped and arrives in your customer without anything out of place. Though challenging to take, measuring the package from the inside provides more accuracy than measuring it from the outside.

This actually helps take care of two very important things;

It helps take care of two essential things;

- Ensures that your product fits in the box snugly

- Leave almost no room for the product to shift while traveling. It provides that your product will not damage in any way.

Why manufacturers do not prefer external dimensions for packaging boxes measurement?

There are several reasons as to why the manufacturers do not prefer external dimensions of packaging boxes:

- External dimensions fail to include the thickness of any packaging box. It may lead to a production of packaging that is not the right size for your product.

- If your measurements are not proper, then the product may have a lot of room for moving around, leading to potential damage to the product!

- In the case of corrugated boxes, this holds especially true. These boxes manufacture a fluted texture present between two paperboards. This aids in making corrugated boxes thick. It adds extra millimeters to the box dimensions; an increase in thickness may not consider if external measurements will consider.

Due to these reasons mentioned above, manufacturers like to take internal dimensions. These are more accurate than external dimensions and help in providing you with quality packaging.

How important is it to take the volume of a packaging box?

Calculating the box’s volume is also a step that you do not want to skip at any cost. A volume of the box helps determine if your product will fit in the packaging box or not. Not only this, but it also aids in evaluating the shipping and distribution processes. Don’t forget that your box’s volume plays a significant role in reducing or increasing the cost of production and building the package.

For calculating the volume, you need to get the measurements of the three dimensions, including; length, breadth, and width. Once you have those, the following is the formula for calculating the volume:

Volume of Packaging Box = Length x width x depth

Remember to emphasize the exact dimensions of your packaging boxes. A stitch in time saves nine, after all. An accurately measured box will give you a lot less trouble than a poorly measured box. It is crucial to understand that your box needs to fit your product like a glove, and it can only do that if you take the dimensions thoroughly!